An In-Depth Guide to MIL-STD-167

Military standard (MIL-STD) testing has laid the foundation for quality and functionality for decades. The MIL-STD-167 is integral to testing rugged server and workstation elements to ensure they can withstand military shipboard environments. Once onboard a ship, sensitive equipment is bound to encounter vibrations. It can only withstand this environment when constructed within the standard’s specifications.

While MIL-STD-180 covers vibration testing for military equipment, MIL-STD-167 delves deeper. It specifically covers rugged servers, computers and other system components for United States Navy ships, which are crucial in naval environments. Everything down to your telescopic slides must meet MIL-STD-167 requirements to maintain the requisite levels of functionality.

Understanding the Military Standard

The Military Standard is a comprehensive set of requirements for products and components intended for U.S. Army and Navy use. While it began exclusively for military applications, its stringent testing and comprehensive requirements became commonplace in commercial environments, elevating quality control across multiple industries.

Today’s standards are enforced by the Department of Defense (DoD), and equipment stability is maintained in challenging conditions. Outside of military applications, the principles of MIL-STD-167 have become relevant in industries including aerospace, automotive and telecommunications. Each of these industries has adopted similar testing protocols. Organizations that integrate these processes into their quality assurance procedures can enhance product reliability and consumer satisfaction.

Applications of MIL-STD-167 across industries raise the bar for all manufacturing operations. It improves product durability and fosters innovation, encouraging manufacturers to explore new materials and designs that better meet performance criteria.

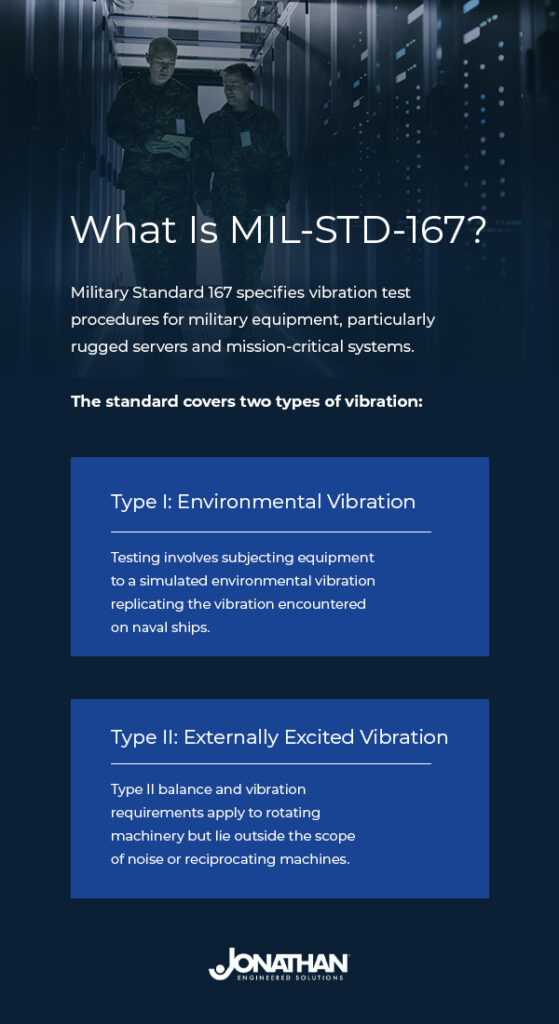

What Is MIL-STD-167?

Military Standard 167 outlines vibration test procedures for military equipment, specifically the effects of vibrations on rugged servers and other mission-critical equipment. Compliance with MIL-STD-167 is essential for any equipment subjected to mechanical vibration or external excitation from rotating components.

In essence, any equipment or server system expected to operate on Navy ships must meet these naval equipment testing standards. Several marine vibration testing standards exist, but MIL-STD-167 is considered specific.

The standard covers two types of vibration:

Type I: Environmental Vibration

The standard applies to type 1 vibration requirements. Testing involves subjecting equipment to a simulated environmental vibration replicating the vibration encountered on naval ships. The vibration test equipment used to achieve these results is of a high standard. If the equipment passes this type of military standard testing, engineers can proceed confidently, knowing it’s unlikely to malfunction or fail during service operation.

Type I equipment vibration testing applies to ships with shafted propeller propulsion. It does not apply to high-speed or surface-effect ships, which produce vibration amplitudes and frequencies above those expected in propeller propulsion ships. Similarly, it does not apply to other propulsion types, including podded and water jet propulsion.

Type II: Externally Excited Vibration

Type II balance and vibration requirements apply to rotating machinery but lie outside the scope of noise or reciprocating machines. It allows for the specification of balance and vibration requirements but primarily focuses on mechanical stability. Together, type I and type II testing provide complementary requirements for the survivability of shipboard equipment.

The Benefits of MIL-STD-167 Testing

MIL-STD-167 military vibration testing standards form the basis for reliability testing for military equipment. They significantly benefit the Navy and industries looking to produce components capable of withstanding challenging operating conditions. They ensure that tested equipment can withstand the vibrations encountered during operation, increasing its reliability and longevity.

MIL-STD-167 testing also helps identify weaknesses in the design phase, ensuring manufacturers and engineers can make necessary equipment improvements before going into service. Much of the equipment subject to this type of testing is mission-critical, and failure could present safety concerns for naval officers aboard ships. Knowing how to comply with MIL-STD-167 ultimately results in cost savings, reducing the need for repairs or replacement due to vibration-induced damage.

Non-military organizations can also benefit from MIL-STD-167 testing. It allows them to ruggedize their equipment, ensuring it can withstand harsh vibration exposures, regardless of the applications. Equipment that achieves MIL-STD compliance is also of the highest possible standard, reducing maintenance and preventing field failures. These benefits are essential for military applications but may also serve commercial industries operating in challenging environments.

The benefits of MIL-STD-167 extend beyond immediate cost savings and reliability enhancements. Manufacturers that adhere to the standard gain a competitive edge in military and commercial settings. Many agencies prioritize suppliers who consistently meet established military standards. These manufacturers can gain a reputation for producing high-quality, reliable equipment, boosting customer trust and loyalty.

History and Evolution of MIL-STD-167

Compliance with MIL standards dates back several generations. MIL-STD-167 was adopted over half a decade ago and has since undergone multiple revisions and additions. Initially, the standard established fundamental guidelines for ensuring the durability of shipboard equipment under vibration stress. This version laid the groundwork for subsequent revisions to address evolving challenges and requirements in naval operations.

MIL-STD-167A supersedes MIL-STD-167-1 to align with the latest technology and vibration requirements. This latest form of testing includes updates to procedures, compliance criteria and specifications to reflect the latest understanding of vibrations and their impact on equipment performance.

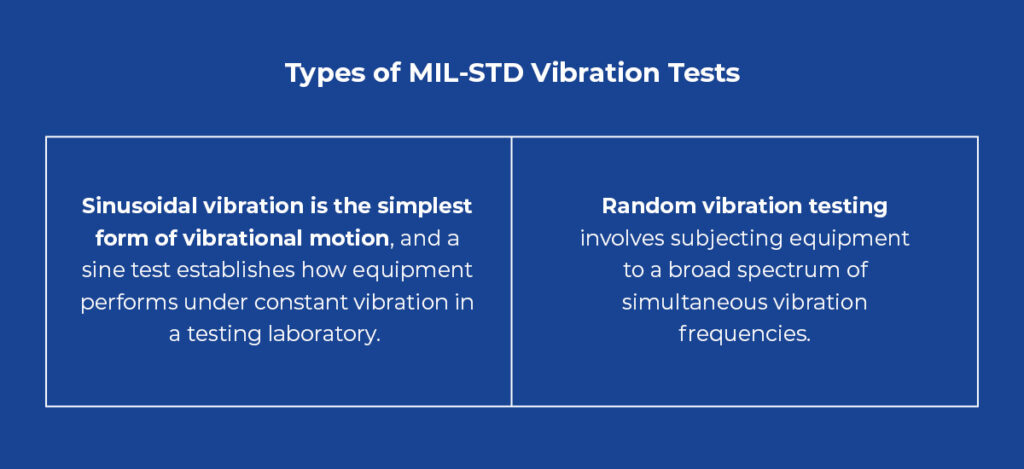

Types of MIL-STD Vibration Tests

Vibration analysis for military equipment requires two principal types of vibration tests:

Sinusoidal Vibration Test

Sinusoidal vibration is the simplest form of vibrational motion, and a sine test establishes how equipment performs under constant vibration in a testing laboratory. It is relatively simple to set up and perform and gives test engineers a clear picture of how to bring the equipment to failure and, thus, under what conditions failure will occur.

Random Vibration Test

Random vibration testing involves subjecting equipment to a broad spectrum of simultaneous vibration frequencies. It’s an effective method of recreating real-world conditions. It allows test engineers to evaluate the equipment’s response and durability during unpredictable situations, such as those on board a Navy vessel. Physical systems are subjected to random dynamic environments, and this test aims to see when these systems will fail.

MIL-STD-167 Testing Procedures

MIL-STD-167 vibration test methods are varied and comprehensive, aiming to ensure the reliability and longevity of naval equipment under intense conditions. Shock and vibration testing under MIL-STD-167 are divided into type I and type II. Within these groups, naval equipment must undergo several tests, including:

Type I: Environmental Vibration Testing

MIL-STD-167 vibration tests are conducted in three principal vibration directions. The test equipment is operational during testing. It’s attached to a vibration table using the points of attachment used when on board a ship. Type I has the following vibration test criteria:

- Exploratory vibration test: This test involves securing equipment to a shock and vibration table. The table vibrates at 4 hertz (Hz) to 33 Hz frequencies at a vibratory single amplitude of 0.010 inches to 0.002 inches. The test engineer records the frequencies that result in functional or structural damage.

- Variable frequency test: In this test, the test equipment vibrates at various frequencies, starting at 4 Hz, with a maximum of 33 Hz. The test is conducted in intervals, and vibrations continue for five minutes per interval. Again, the test engineer observes and records any damage or changes in equipment performance.

- Endurance test: The endurance test uses the data from the previous tests and then tests the equipment under further vibrational stress. The test professional vibrates the equipment for two hours at the same frequency, which results in changes during the exploratory vibration and variable frequency tests.

- Endurance test for mounted equipment: Mounted equipment undergoes a slightly different test to compensate for rough weather factors at sea. This test included static loads of 2.5 gravitation acceleration applied in vertical and transverse directions. The tester vibrates the equipment for at least two hours at 33 Hz provided the equipment complies with predetermined expectations or the test engineer notices response prominences.

Type II: Internally Excited Testing

These tests define balance and vibration requirements for rotating machinery. They aim to stabilize rotary machinery, reduce the effects of unstable rotating components and minimize internally induced vibration. This category of tests also defines rotor characteristics and the revolutions per minute (RPM) at which the machinery operates. It also details the balancing and procedures for equipment operating at the required RPM.

Internally excited testing involves a single vibration test. The test engineer installs the equipment at a natural frequency that is below 25% of the minimum operating speed expected in real-world applications. They then note whether the vibrational displacement amplitude is over the predetermined frequency and amplitude.

Testing Procedures and Protocols

To meet MIL-STD-167 requirements, test equipment must go through specific testing procedures and protocols, from preparation and documentation. Some of these steps include:

- Test preparation: Before test engineers can perform the test, they must ensure the equipment is in proper working condition and can perform the desired tasks. They must then secure the equipment in a compliant test setup that simulates shipboard conditions, including mounting to specific attachment points if necessary.

- Test execution: During execution, test engineers must operate within stringent MIL-STD-167 testing parameters. The primary objective is to simulate engine vibrations or rough sea conditions.

- Documentation and reporting: Test engineers record detailed observations during the process, outlining vibration levels and duration. They document any damage or equipment failure and the Hz but nothing about the specific conditions in which they occurred. At the end of the test, they complete a comprehensive report detailing the results and observations. This information can be used to improve future equipment design. The documentation includes a test plan, test report, and any exemptions as determined by the test engineer.

The equipment is deemed acceptable if it retains its ability to perform principal functions during and after the vibration tests are complete. Minor damage or distortion is permitted, provided it does not interfere with the equipment’s ability to perform those functions.

As the standard covers multiple equipment types, it can be challenging to discern whether a failure is minor or more severe. The test engineer makes a determination during the trial. In general, significant failures cause malfunctions over long periods.

MIL-STD-167 Compliance

STD-167 is a comprehensive standard that has specific compliance guidelines. Any engineer or manufacturer wanting to make high-quality equipment must adhere to the requirements outlined in the standard to achieve the goal of placing it aboard naval vessels. If equipment conforms to these standards, it can continue functioning in the intended environment. According to the standard, equipment with unspecified compliance may fail at critical moments.

One crucial aspect of MIL-STD-167 compliance is conducting test procedures according to the prescribed guidelines. Any deviation from these protocols can affect the equipment’s performance in real-world situations. In contrast, following the procedures in the letter allows engineers to assess the equipment’s performance and identify and address any weaknesses.

Documentation is as critical to achieving MIL-STD-167 compliance as the testing processes themselves. Accurately documenting detailed records of testing procedures, results and observations is essential to demonstrating compliance. This documentation is a reference for future assessments and provides valuable insights into the equipment’s performance. Manufacturers can use this information to inform future designs, adopting a posture of continuous improvement.

Challenges and Best Practices

Due to the complexity of MIL-STD-167 vibration testing, test engineers must overcome several challenges to ensure accurate results. Vibration testing equipment and the associated setup can be complex and time-consuming. Any errors in the test setup can affect the results, potentially sending non-compliant equipment into operation. Test equipment must be properly calibrated and maintained to meet the standard’s requirements. Interpreting the results can be just as challenging, and test engineers need specific skills to handle complex vibration data.

The following best practices can help test engineers overcome these challenges:

- Training: Test engineers and other personnel conducting MIL-STD-167 testing should have comprehensive training to overcome any obstacles associated with the testing process.

- Calibration checks: Vibration testing equipment is often highly sensitive. Organizations conducting MIL-STD-167 testing should calibrate their equipment and conduct regular maintenance to ensure accurate and reliable results.

- Strict adherence to testing procedures: Any deviation from testing procedures can result in noncompliance. MIL-STD-167 outlines comprehensive procedures that must be followed to achieve the standards of operation required for naval operations.

- Continuous improvement: Implementing a process for continuous improvement based on past test results can enhance equipment performance and reliability in the future.

- Collaboration: Engineers, designers and quality assurance professionals must collaborate throughout testing and consider all product design and functionality aspects. Regular collaboration can help teams identify issues early on in the development process. A proactive and collaborative approach enhances compliance and promotes a quality culture across organizations.

Speak with a Sales Representative

Our representatives have a wealth of knowledge on all our products – let them steer you in the right direction.

Learn More